Appropriate Technology, Inc

Appropriate Technology was incorporated on July 15, 1992 in Florida to provide a business framework for providing product design and engineering services to industry and the general public. In the nearly 30 years of operation we have been heavily involved with the design of high pressure compressor systems for the fire market. We have also designed products for the medical field and provided engineering support for the safety department of a major hospital.

Our director of technology is a Professional Engineer licensed in Florida and has 60 years of diverse experience in nuclear power plant design and operation, high pressure compressor systems design, medical systems safety research and a host of specialty product development. Equipment reliability and maintainability in these fields is of paramount importance. Maintainability is in large measure a function of how well the product is documented. The compressor system we are offering will easily pass the most demanding standards of the nuclear industry and all of the applicable regulating agencies.

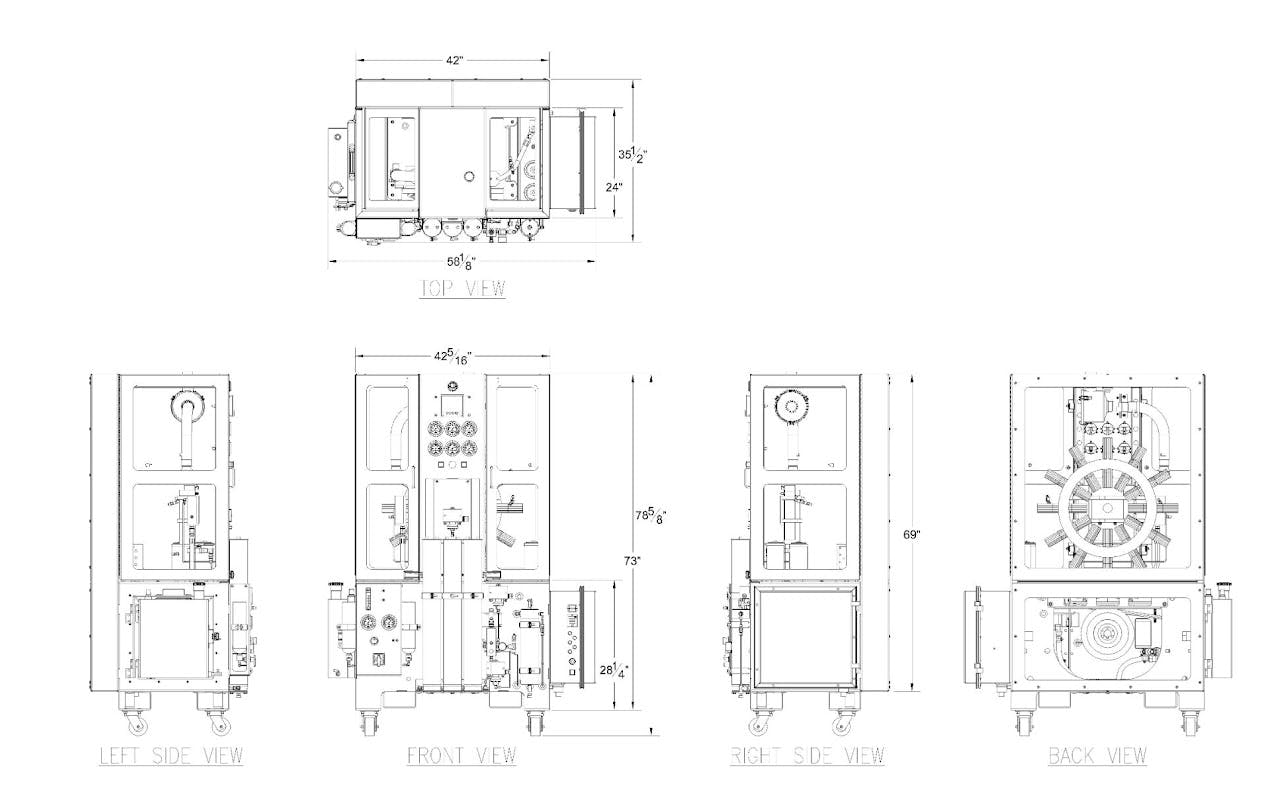

Available for Immediate Sale | Twenty six SCFM 6000 PSIG Breathing Air Compressor System

Appropriate Technology has a high pressure breathing air compressor in stock and ready for immediate sale. This machine has been designed and constructed with the highest quality American made products when they are available and meet our stringent specifications. The most important component is the compressor block which is made in Ocala, Florida by L&M Compressor. The sheet metal is laser cut, formed, and coated with high quality automotive acrylic enamel paint by OFAB in Ocala, Florida. The unit is assembled and tested in Ocala, Florida.

Machine Features

• It is a fully integrated high pressure compressor system. No additional components are required for operation. Simply wire the machine to name plate specified house power and connect the air discharge port to the receiver with appropriately rated tubing or hose.

• This machine is fully tested and ready for service after minimum preservice inspection and set point verification.

• Industrial grade components used throughout.

• Precision formed laser cut sheet metal components.

• Unprecedented access for maintenance.

• Cabinet sized to fit through standard door.

• 12 Vdc control system.

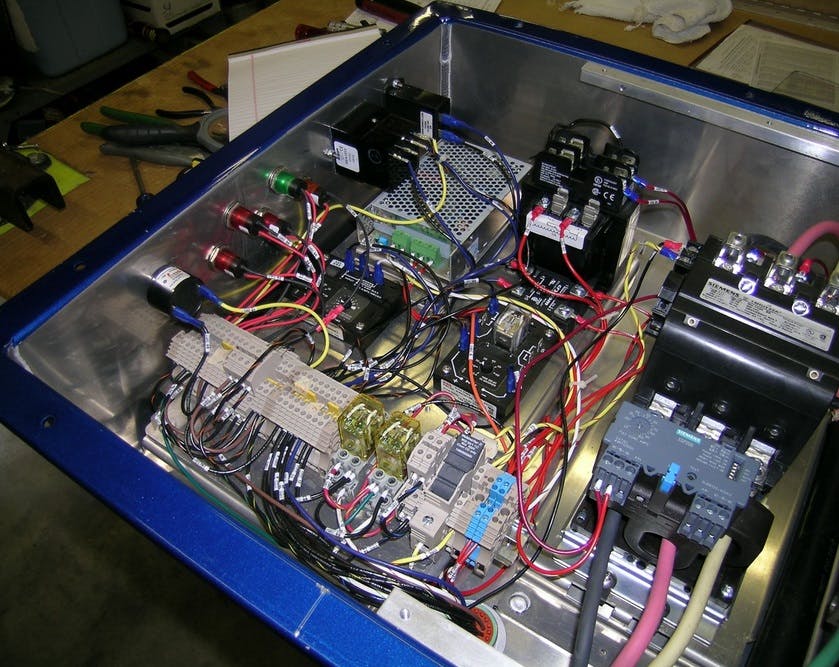

• Spacious custom made Aluminum electric box with arc flash protection over high voltage components.

• Quiet, smooth, 5 stage L & M compressor block. No acoustical insulation required to meet OSHA noise standard for unlimited exposure.

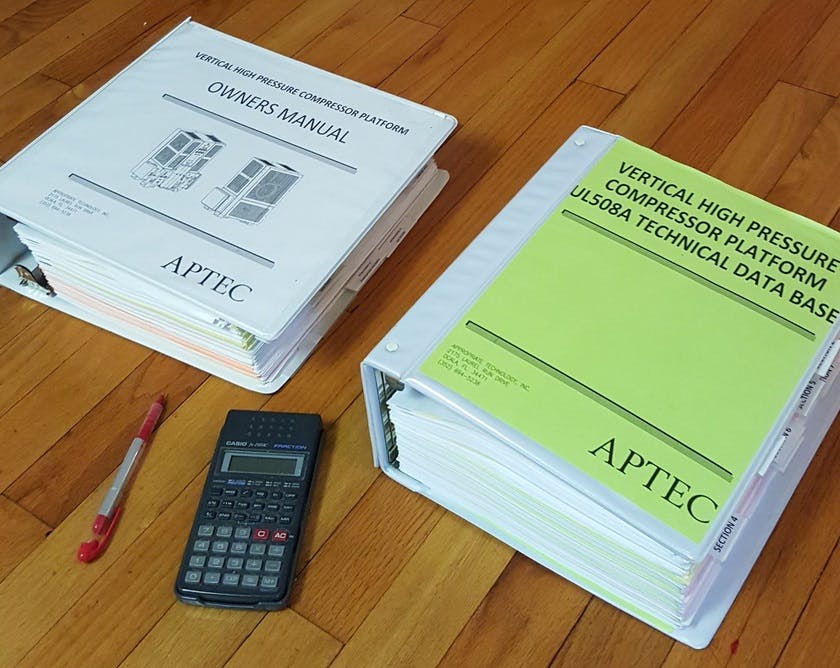

• Comprehensive Owner’s Manual.

• Comprehensive UL508a compliance manual.

• Highly reliable Bagotronix air purity monitor with remote access via internet.

• GOTCO air purification system that uses Lawrence Factor disposable filters.

Maintenance Friendly Features

• Front Mounted Purification

• Front Mounted Ashcroft Pressure Switches (Air and Oil)

• Front Mounted Air Sample Port

• Easy Access Manifold Mounted Pressure Maintaining Valve (PMV)

• Detachable Fork Lift Loops

• Extraordinary Access to Compressor via Hinged Doors

• Easily Removed Expanded Metal Rear Panels

• Removable and Transportable Blow Down Reservoir

• Convenient Front Mounted Compressor Oil Drain Port

• Front Mounted Air Monitor Calibration Subsystem

• Conveniently Mounted Replaceable Element Inlet Air Filter

• Front Mounted Final Separator With Manual Drain Valve

• Moisture Monitor Probe Mounted In Discharge Manifold

• Swagelok Bite Type Fittings Used In High Pressure Lines

• Spacious Custom Aluminum Electric Box With Lift Off Hinged Door

• DIN Rail Mounted Weidmuller Terminal Components

• ¼” Thick Al Control Component Mounting Plate with tapped machine screw holes

• Color coded and numbered control system wiring correlated to simple schematic

• Easy Access To Dual Blowdown Exhaust Filters

• Reusable fasteners, Nylok Nuts used on all cabinet bolts, zero use of drill screws

Operator Conveniences

• Panel Mounted Stage Pressure Gauges

• Panel Mounted Oil Pressure Gauge

• Panel Mounted Intake Filter Differential Pressure Gauge

• Panel Mounted On/Off Switch

• Panel Mounted Emergency Stop Button

• Panel Mounted Fault Light

• All Instruments Clearly Labeled

Implemented Options

• Motor Size: 20 HP, 3 Phase, 230 v ODP Leeson Motor Note: Can be rewired for 460 or 208 voltage power supply.

• Bagotronix Air Monitor

• Dual Ashcroft Pressure Switches

• Removable Blowdown Reservoir

• Removable Swivel Casters

Tap the button to contact us by phone

We are available:

Monday-Saturday 9am-5pm

Contact Information

2175 Laurel Run Drive

Ocala, Florida 34471

Email: sambaggett@cox.net

MAJOR COMPONENTS AND FEATURES

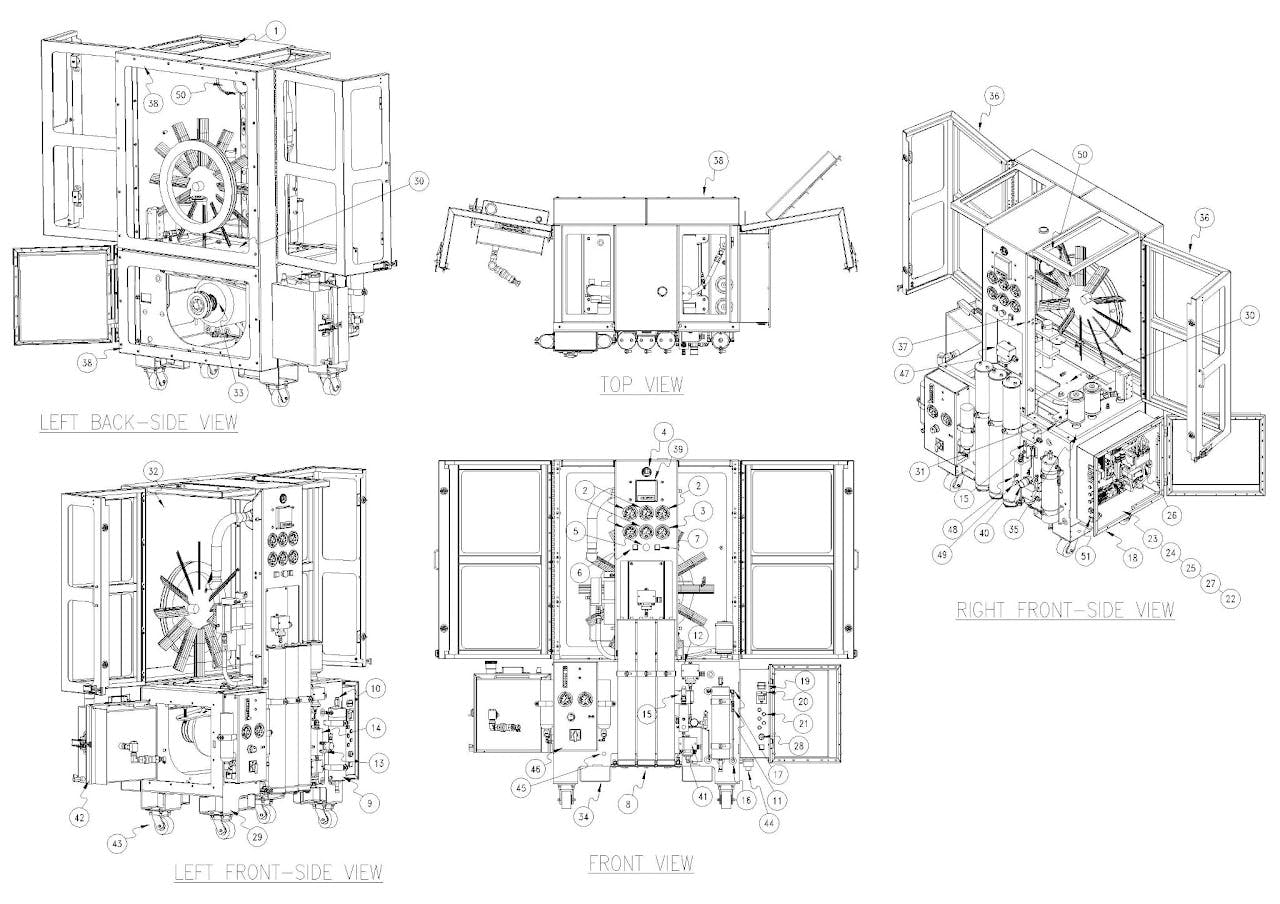

1. Remote air intake

2. Panel mounted stage pressure gauges

3. Panel mounted oil pressure gauge

4. Intake air filter differential pressure indicator (Filter Minder)

5. Panel mounted IDEC emergency stop switch

6. Panel mounted IDEC illuminated start/stop switch

7. Panel mounted IDEC fault light

8. Front mounted purification system (can use cylinders from all major manufacturers)

9. Front mounted final separator with manual drain valve

10. Separator mounted relief valve

11. Inline check valve in separator discharge line

12. Easily accessible front mounted Ashcroft pressure switch

13. Front mounted air sample port

14. High strength Aluminum discharge air manifold with chamber for moisture monitoring probe

15. Manifold mounted pressure maintaining valve (PMV)

16. Rubber grommets in all penetrations where wires or tubing pass

17. Swagelok bite type fittings used in high pressure air applications

18. Custom 20” X 20” X 10” deep Aluminum electric box with lift off hinges on access door.

19. Electric box mounted hour meter

20. Electric box mounted maintenance timer

21. Electric box mounted status lights

22. IDEC 50 watt 12v DC switching power supply

23. Micron 150 VA transformer

24. Weidmiller DIN rail terminals

25. Crydom 25 amp solid state switch

26. Siemens Furnas motor contactor (Starter)

27. SSAC solid state timers

28. Electric box mounted audible alarm for fault conditions

29. Precision laser cut all sheet metal frame and base construction

30. 3/8” thick two piece formed compressor and motor base

31. Rubber cushion compressor/motor base suspension for vibration isolation

32. Compressor package can accommodate L&M, MAKO, Hamworthy, Coltri, Bauer blocks

33. Compressor package can accommodate motor sizes ranging from 5 HP to 30 HP TEFC

34. Detachable fork lift loops

35. Two chambered auto drain blow down expansion tank with dual exhaust filters

36. Extraordinary access to compressor and panel mounted instruments via vertically hinged doors

37. Safety switch door interlock (shuts machine down when either door is opened)

38. Easily removed expanded metal screens in wind box if additional maintenance access is desired

39. Bagotronix Air Monitor

40. Manifold mounted regulator for CO sensor sample air

41. Dual Ashcroft pressure switches

42. Removable blow down reservoir

43. Removable swivel casters

44. Five input power wiring options

45. Convenient front mounted compressor oil drain port

46. Air Monitor calibration subsystem

47. Ashcroft oil pressure switch

48. Air sample port

49. Air drain valve

50. Solberg replaceable element inlet filter

Tap the button to contact us by phone

We are available:

Monday-Saturday 9am-5pm

Contact Information

2175 Laurel Run Drive

Ocala, Florida 34471

Email: sambaggett@cox.net

Training

Operator Training At Machine Delivery

Optional Maintenance Training at your site or at the factory. (Request a Quote)

Warranty

Provided by L&M Compressor

Origin of the concept 'Appropriate Technology'

The origin of the term “Appropriate Technology” can be traced to an amendment to the Foreign Assistance Act in 1975. The amendment provides for $20 million dollars to be spent over three years to promote technology appropriate to developing countries and instructs the Agency for International Development (AID) to draw up a proposal to spent the money and involve the private sector in the project. Appropriate Technology International (ATI) is the sub-agency created to pursue the Congressional mandate.

ATI was an effort to reshuffle US aid priorities in the direction of the voguish “small is beautiful” approach. That viewpoint holds that what the rich of the world have been giving or selling to the poor reflects their own values and needs rather than those of the people they are trying to help. Thus, what US aid programs had dispensed for 25 years before the enactment of the ATI had been capital and energy “guzzling”, managerially complex and, above all, not labor intensive, despite the fact that receiving countries like Jamaica, Zaire and Indonesia had unemployment rates hovering around 30 to 40 percent.

So, what would be appropriate? Well, the marvel of a great idea is its capacity to appear self-evident. The high priest of “small is beautiful,” E. F. Schumacher, advanced the notion that the proper way to deal with man and technology in the development process is to reverse the capital-energy-labor predicament by designing and supporting aid projects that generate jobs through methods of production that have developed naturally. Don’t send the 125 horsepower tractors that are the heart of the American production system to countries like Egypt, Bangladesh and Taiwan where the average farm is only two to three acres. They are too big, too expensive—in a word, “inappropriate.” The entrepreneurs who farm these tiny plots needed improved technology no less than American farmers, but they needed machines and tools appropriate to their tiny farms and cheap enough to fit their low incomes.

As a Regional Marketing Manager for a nuclear industry think tank one of my most important assignments was to seek out and recognize emerging trends in government spending on technology. The paragraphs above were gleaned from an article in the June 11, 1977 issue of the New Republic. The article stimulated a more encompassing or global interpretation of how to design products…instead of seeking the latest high tech solution to a design problem or some low tech kludge a designer should make a considerable effort to identify the solution that is most appropriate when all physical and financial factors are considered. It is one of the most basic mission elements of Appropriate Technology, Inc., that is, to always seek the most appropriate technology to solve design problems unless otherwise specified by a client.

The use of Programmable Logic Controllers (PLC's) in high pressure breathing air compressor control is an example of inappropriate use of high technology. These machines are either ON or OFF. They typically have an ON/OFF Switch, an Emergency Stop Switch, a pre-set pressure switch that starts and stops the machine based on receiver pressure, an oil pressure switch that shuts down the machine if the oil pressure drops below a preset limit, a carbon monoxide monitor that shuts down the machine on high CO in the air stream, and a bimetal temperature switch that shuts the machine down if the compressor block rises above a preset temperature limit. This approach to machine control is called the “electro-mechanical” approach. Historically electro-mechanical controls are less expensive than PLC based systems, easy to trouble shoot, and easy to repair. PLC control systems must be programmed by high paid ($150.00/hr.) specialist and many of the components required in an electro-mechanical approach must be used in a PLC based control system also. Another damming characteristic of PLC programmers is that they will not trouble shoot someone else's work…they throw it out and start all over with new programming according to their quirks.

The implementation of machine health diagnostics is the only driving force for implementing anything other than an electro-mechanical system. An embedded computer system which is programmed in a low embedded system level language such as C++ is the best solution for a control and instrumentation system with diagnostics. Virtually any computer science student can program in this language so machine developers are not beholding (hostage) to the global control system component monopolies.

Samuel M. Baggett, BSME, BSNE, PE (60 years of diverse machine and system design)

Fire Market Business Opportunity

The Appropriate Technology high pressure breathing air compressor system is a highly developed and documented product that has industrial and fire market appeal. If you or your company is interested in manufacturing and marketing this product please call Sam Baggett at 352-362-4712. Minimum investment requirements include purchase of the prototype machine and a fee to transfer the considerable design data base. A royalty arrangement may be negotiated to recover our developmental costs. Reasonable consulting fees can be negotiated for assistance in addressing fire and industrial market opportunities.